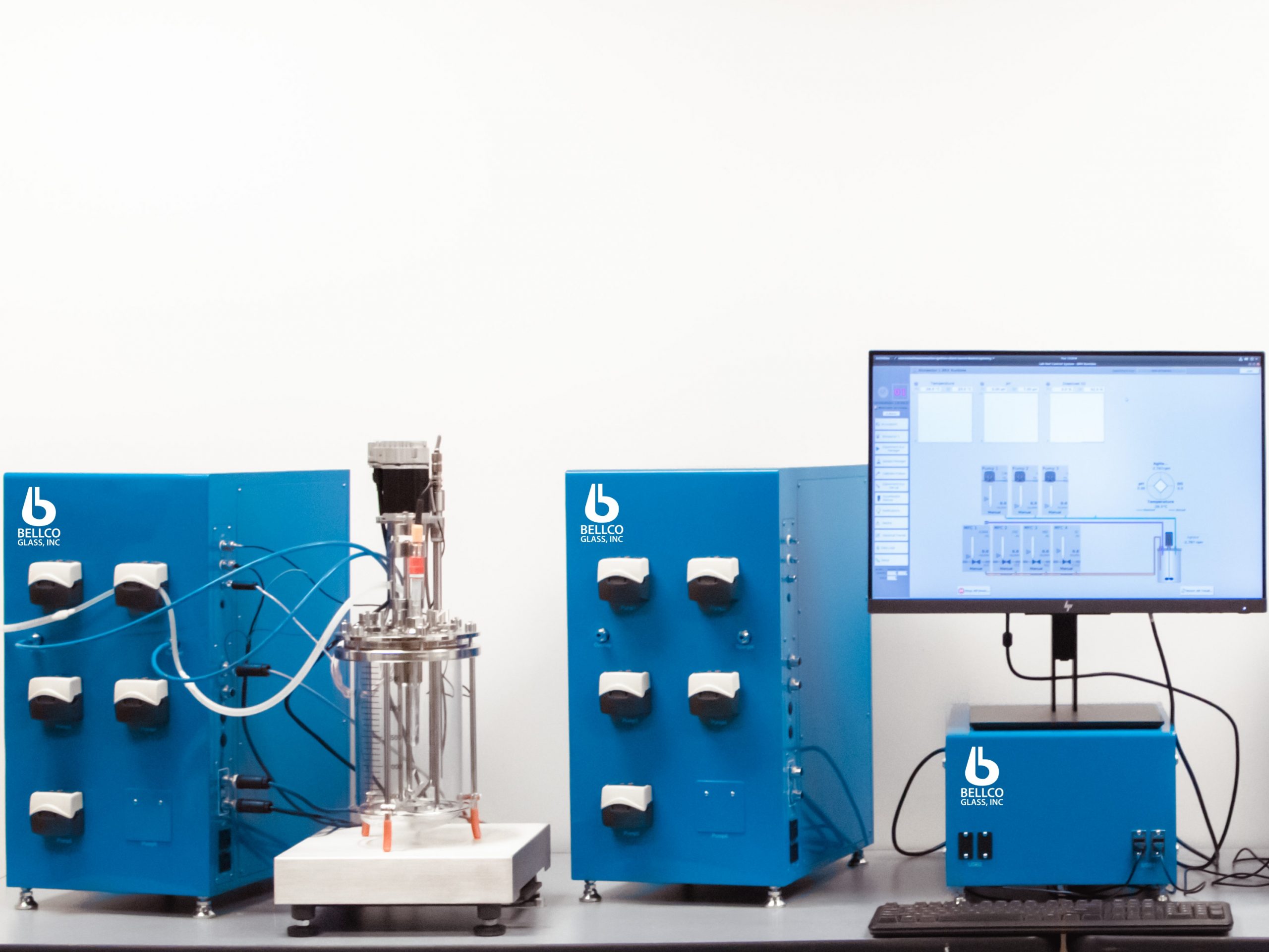

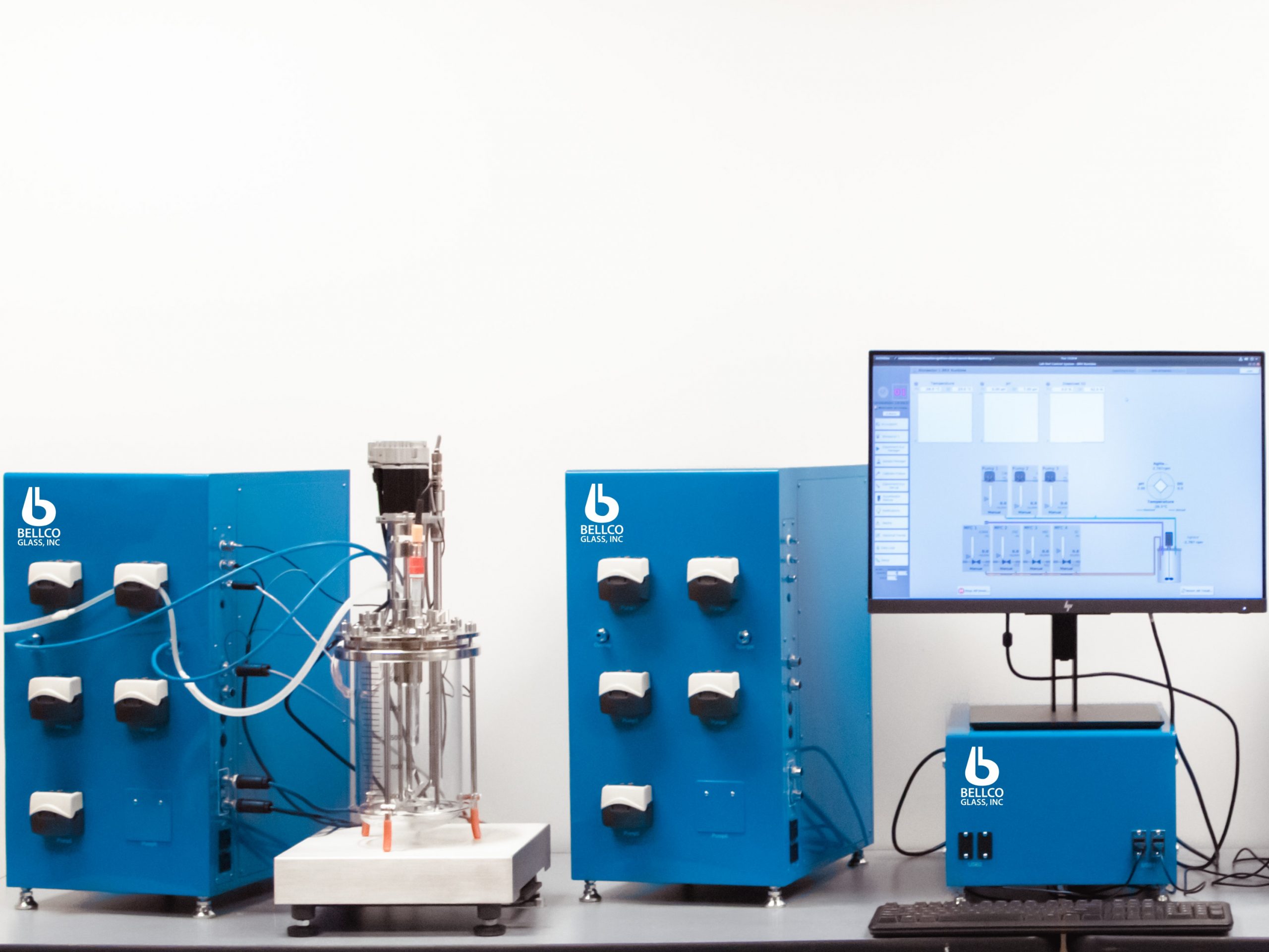

Bioreactor System

Description

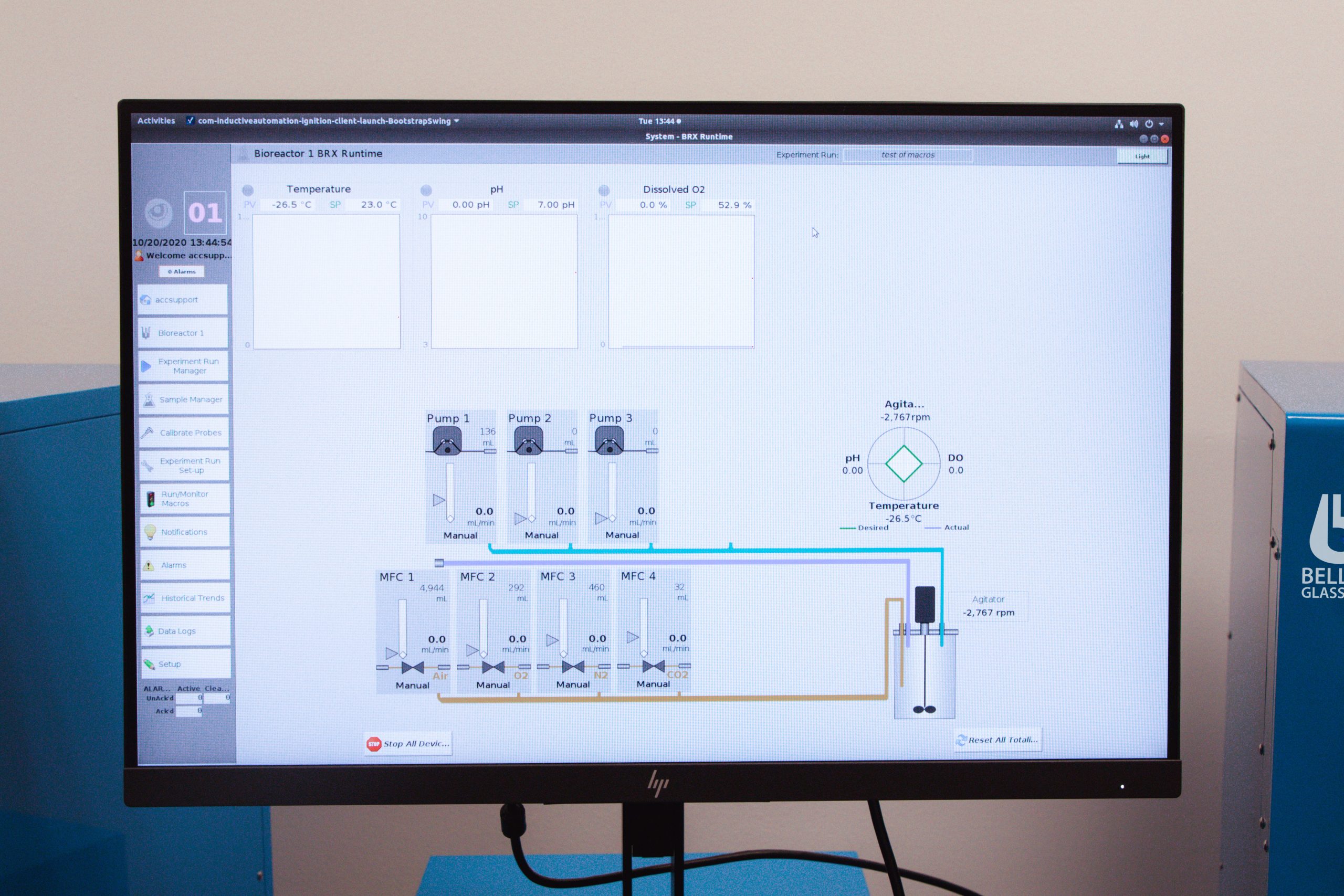

Control Features

• DO (bi-directional)

• pH (separate acid/base tuning

• Temperature (heating/cooling)

• User configurable input

• Multi step cascade of DO, pH and user input loops to any combination of pumps, gas flows and agitator

• Linear and Exponential Pump Ramping Modes

• Change by time and volume or flow rate or by gain or loss in weight with scale

System Capabilities

• Standard supervisor controls up to 16 bioreactors (8dual or 16 controllers)

• Redundant options are available for larger systems

• Expandable to 80 bioreactors

• OPC UA compatible

Software Features

• Lab dashboard ( all reactors) control individual reactors

• Historical collection (process parameters)

• Log alarms and events to SQL data base and configurable as absolute or relative

• Calibration Wizards (drive accuracy and consistency of DO and pH readings

• 21CFR11 user management full audit trial

• Manage experiment data (Log Start and end of experiments) (create custom markers to log events such as induction, feeds and samples during run)

• Manage samples (enter corrections to DO and pH reading

• Data retrieval by time or experiment for trend viewing or export to csv

• User configurable: Notifications via e-mail or text based on process conditions or time period

• User defined Macros for recipe setpoint download or advanced coordination of setpoint changes or device control based on time or process condition

• Remote access for service and support via outbound only port