Roller Apparatus

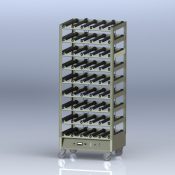

Fixed Frame Roller Apparatus

The Bellco Cell Production Roller Apparatus has been designed for

production of animal cells, viruses and cell products. Modular units are

available from 5 to 45 bottle positions and allow easy expansion with

modular add-on decks. Non-modular production units come in 45 and

50 bottle positions with over 80,000 cm2 of surface area. Rollers have

a key design to eliminate slipping and are easily removable for servicing

of bearings. Rollers are formulated from a chemical-resistant non-slip

EPDM. All units feature a solid state control with heavy-duty DC motor

and analog tachometer. Non-modular production models feature rubber

bumpers, handles and a slotted rear guard. Optional All Position Drives

are available for use with plastic roller bottles to prevent slipping of

the light-weight bottles. An optional Stand By Drive and Alarm System

provides motion and power failure alarms and has a redundant drive system that automatically drives the unit should the primary fail.

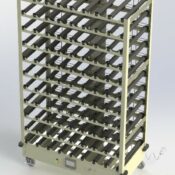

Modular Cell Production Roller Apparatus

The Bellco Cell Production Roller Apparatus has been designed for production of animal cells, viruses and cell products. Modular units are available from 5 to 45 bottle positions and allow easy expansion with modular add-on decks. Non-modular production units come in 45 and 50 bottle positions with over 80,000 cm2 of surface area. Rollers have a key design to eliminate slipping and are easily removable for servicing of bearings. Rollers are formulated from a chemical-resistant non-slip EPDM. All units feature a solid state control

with heavy-duty DC motor and analog tachometer. Non-modular production models feature rubber bumpers, handles and a slotted rear guard.

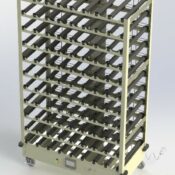

Process Bottom & Top Drive Roller Apparatus

The Bellco Process Controlled Bottom Drive Roller Apparatus holds up to 53 (see specifications below) full size glass or plastic roller bottles (110 to 120 mm diameter and up to 510 mm in length). The unit features a brushless DC motor and controller that operate at bottle speeds ranging from 0.3 to 9.0 rpm with the ability to select clockwise or counter clockwise direction. Units feature brushless, maintenance-free DC motors with drive assemblies designed for quiet operation. Four corner bumpers and two locking castors (on the front wheel positions) are also provided. Rollers are easily removed for replacement by using the special tool provided with each unit. All-Position Drive facilitates the use of lightweight plastic roller bottles by ensuring rotation at each bottle station, independent of any load configurations. The unit has an RS-485 communication port. This RS-485 port is provided for process control and

monitoring by a remote controller (e.g. Computer). It provides communications to the controller using standard RS-485 protocols through an RJ-12 Jack. It is designed to be used with standard laboratory networking software, but may be used with any custom software that supports RS-485 communication.

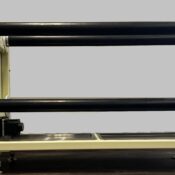

Digital Bottom & Top Drive Roller Apparatus

The Bellco Digital Bottom Drive Roller Apparatus holds up to 53 (see

specifications below) full size glass or plastic roller bottles (110 to 120 mm

diameter and up to 510 mm in length). The unit features a brushless DC

motor and controller that operate at bottle speeds ranging from 0.3 to 9.0

rpm with the ability to select clockwise or counter clockwise direction. The

digital display panel has a 0.46” LCD for easy reading and the apparatus has

a locking speed knob. Four corner bumpers and two locking castors (on the front wheel positions) are also provided. Rollers are easily removed for replacement by using the special tool provided with each unit. All-Position Drive facilitates the use of lightweight plastic roller bottles by ensuring rotation at each bottle station, independent of any load configurations.

Showing 1–16 of 30 results

-

Digital R/A 10 Decks Brushless 115V, Fixed Frame

$10,465.11 Add to cart -

11 Deck Roller Apparatus, 115V SKU:7360-S0007

Read more -

11 Deck Roller Apparatus, 230V SKU:7360-S0010

Read more -

2 Position Brushless Roller Apparatus, 115V SKU: 7623-01020

$2,059.22 Add to cart -

2 Position Brushless Roller Apparatus, 230V SKU: 7623-01220

$2,308.89 Add to cart -

5 Gallon Roller Apparatus SKU: 7400-S0026

Read more -

Digital Roller Apparatus 9 Decks Brushless 230V, Fixed Frame

$10,245.39 Add to cart -

Bench Top 2 Position Modular Deck Only SKU: 7632-10000

$600.62 Add to cart -

Bench Top Roller Apparatus 115v 10 Position w/ All Position Drive SKU: 7620-02005

$3,473.64 Add to cart -

Bench Top Roller Apparatus w/ All Position Drive

View products -

Back-To-Basics II Bench Top Roller Apparatus 115v 2 Position Base Only SKU: 7632-00115

$1,448.98 Add to cart -

Back-To-Basics II Bench Top Roller Apparatus 2 Position Base Only

View products -

Bench Top Roller Apparatus 230v 10 Position w/ All Position Drive SKU: 7620-02220

$3,438.81 Add to cart -

Back-To-Basics II Bench Top Roller Apparatus 2 Position 230v Base Only SKU: 7632-00230

$1,694.94 Add to cart -

Bench Top Digital Roller Apparatus 10 Position

View products -

Bench Top Digital Roller Apparatus 115v 10 Position SKU: 7621-20115

$3,822.43 Add to cart